Stable timber and faster drying time with SAUNO.

Sauno manages temperature and humidity for fast, effective wood drying.

If you have the time, letting the wood dry by itself is an old, well-tried method. This is sufficient for most people. A faster way is to dry the timber in a wood drying kiln. The Sauno wood kiln gives you energy-efficient drying and a perfect result.

The Sauno method is a process in two steps – drying and steaming.

The first step is the steaming process at 70°-75° which opens the pores of the wood. The second step is the drying process. It happens at a temperature of 40°- 50° and the moisture is slowly evaporated from the centre of the timber. The risk for drying cracks is in that way reduced to a minimum.

Within a week you have dried pine ready for planing and moulding. You get less cracks and distortions compared to air dried timber. By building the cabinet yourself, the investment cost becomes low compared to other solutions. And for hardwood – the Sauno method fastest way we know of to produce quality kiln dried native and exotic timber.

New model WDU!

Our upgraded and improved Sauno WDU drying unit of 2 kW, with powerful fan action for air circulation in your drying chamber. The unit also has an integrated air intake that draws air into the dryer by means of the underpressure formed in the air stream. The dry and cold outside air is mixed with the heated, moist air in the Sauno drying unit before reaching the wood in the chamber. These are features that give a more uniform and controlled drying result.

New Drying Tent

Currently, the drying chamber comes in one size. We have made it considerably larger than its predecessor. The internal length is almost 3 m, and the width 70 cm. The height is 1.1 m at the lowest point of the roof, but it slopes upwards to a height

of 1.4 m at the opening, to facilitate loading in the timber.

”It comes with aluminium feet, which are used for lifting the timber stack from the floor to allow the air to circulate freely. Loading in timber is easy, since the entire front side can be opened. Spacers, e.g. strips of wood, are placed centred above each other between the layers of boards. They should be dry and of the same thickness as the wood that is to be dried, to create enough space for circulation. Also, leave some lateral space between the boards, and between the stack and the walls of the chamber,” says Mattias Byström, Vice President at LOGOSOL.

Do you need a wood drying kiln?

In most cases, air drying the timber outdoors is the best method. But for certain purposes joinery-dry timber is required, and then you will need a wood drying kiln.

We recommend the Sauno wood drying kiln to you who:

- want to avoid that your finished products crack or warp.

- have the opportunity to get hold of slightly unusual wood types that you want to use in your joinery.

- are making doors, furniture or windows.

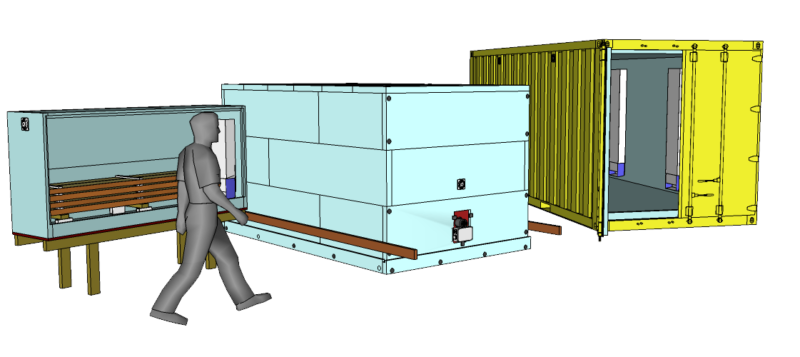

| What kiln cabinet should I build? Any well insulated cabinet can work, as long as it doe snot leak steam, draft, and has a tanked bottom. XPS foam panels – easy to construct. Steel insulated fridge panels – robust. Insulated plyboard or marine ply – can work well if suitably damp/water proofed. Shipping containers – when insulated can fit multiple VT kiln units for larger scale drying situations. |

Build your own drying cabinet to suit your dimensional requirements; or use our own portable drying tent which is suited to a single WDU.

For example:

Our drying tent requires one wood drying units, however your own design can be larger and incorporate multiple WDU.